Service Requirements

Food Production Requirements

- Production Control

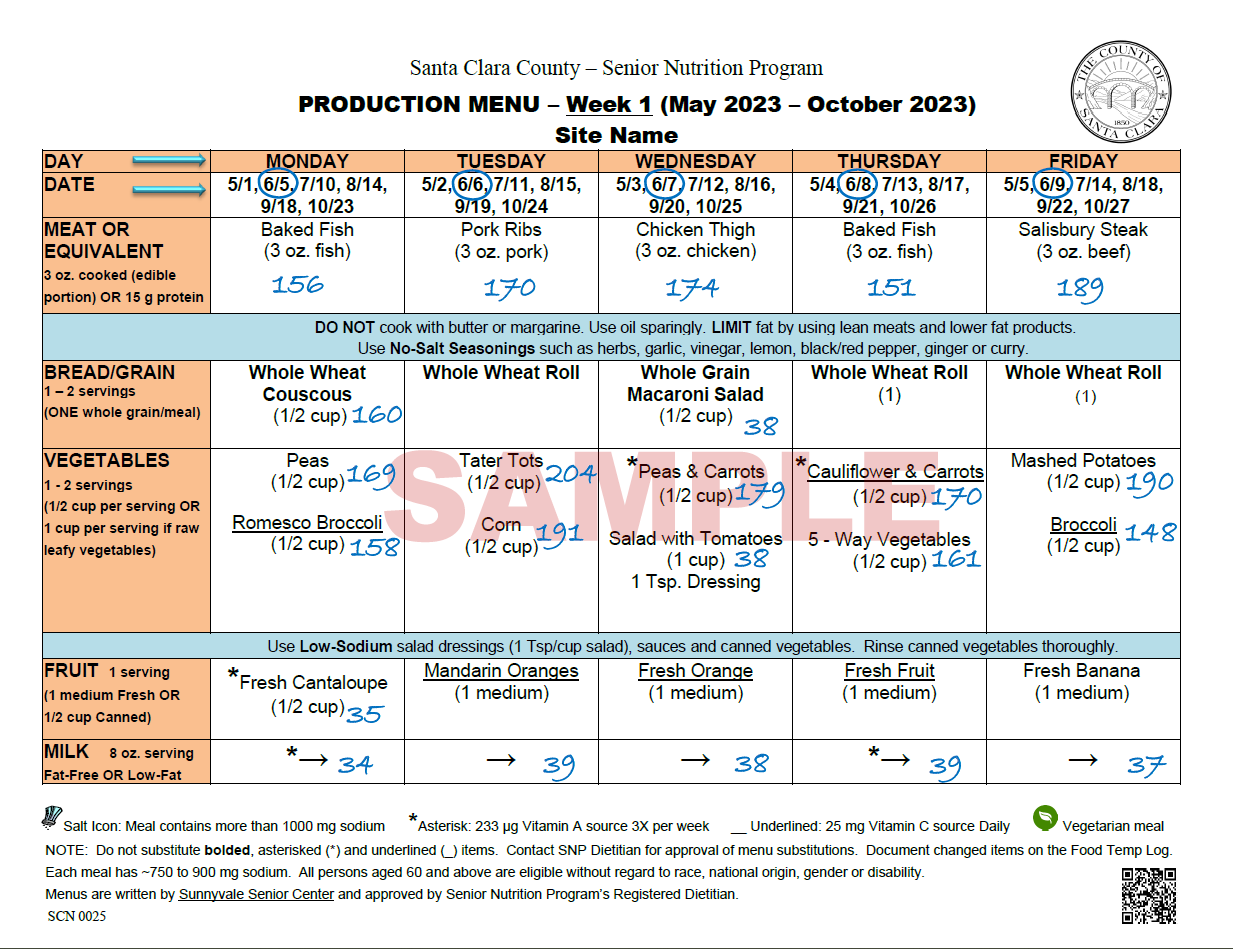

- Food production schedules or worksheets shall be available in the food prep area.

- Food shall be prepared or ordered in sufficient quantities to serve all participants. Careful planning shall minimize leftover food and prevent waste.

- Standardized recipes are recommended to ensure consistency of quality and quantity and adherence to menu guidelines. Follow the HACCP (Hazard Analysis Critical Control Point) guidelines as listed in the Food for Fifty recipe book (current edition).

- Appropriate utensils for correct and consistent portion control shall be used.

- All frozen meat, fish, poultry, and shellfish shall be kept frozen until cooking begins.

- Use proper cooking Temperatures. See list below and CalCode Section 114004 for further cooking temperature requirements.

Food Item Cooking Temperature Seafood 145ºF Eggs and food containing eggs 145ºF Pork 145ºF Ground beef or any food containing ground beef 155ºF Poultry and any food stuffed with fish/meat/poultry 165ºF

- Potentially Hazardous Foods (CalCode, Section 113871)

- Potentially hazardous foods (PHF) are capable of supporting rapid and progressive growth of microorganisms which may cause food infections or food intoxications.

- PHF include, but are not limited to: Milk, meat, fish and shellfish, and fresh eggs; stuffing, gravies, cooked vegetables, starches such as cooked rice, potatoes, and beans; desserts made chiefly from milk and eggs such as puddings and cream pies; salad dressings with a low acid content; and sliced melons, seed sprouts, tofu, and fresh garlic.

- Foods that are acidic, low-protein, low-moisture, high-sugar, or high-salt content are generally not considered hazardous. Examples: canned fruit, vinegar-based salad dressings, breads, and rolls.

- Potentially hazardous leftover foods shall be discarded, unless they are properly cooled and stored for later meal service.

- Thawing of Potentially Hazardous Foods (CalCode, Section 114018)

All frozen meat, fish, poultry, shellfish, and frozen potentially hazardous foods shall only be thawed in one of the following ways:- Defrosted in a pan on the bottom shelf of a refrigerator that maintains the food temperature at 41˚F or below; or

- Completely submerged under potable running water for a period not to exceed two hours at a water temperature of 70˚F or below, and with sufficient water velocity to agitate and flush off loose particles into the prep-sink; or

- Defrosted in a microwave oven; or

- Defrosted as part of the cooking process.

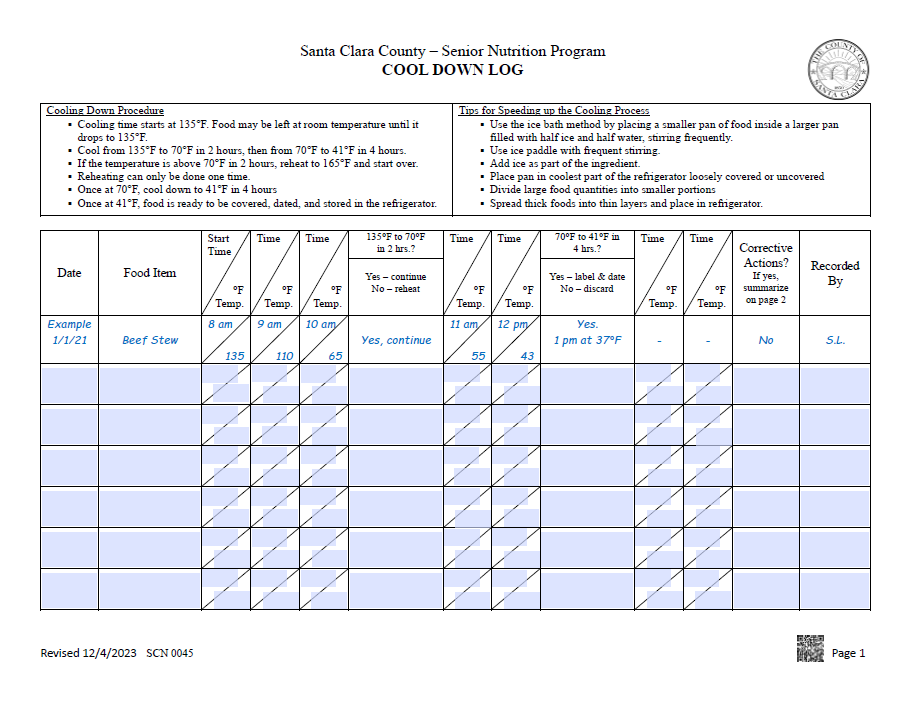

- Cooling of Potentially Hazardous Foods

Follow the Cooling Procedures to cool food safely (Form: Cool Down Log):- Cool PHF products from 135˚F to 70˚F within two (2) hours. (CalCode, Section 114002b)

- From 70˚F, cool to 41˚F within four (4) hours. (CalCode, Section 114002b)

- Potentially hazardous food shall be cooled within four (4) hours to 41˚F or less if prepared from ingredients at ambient temperature, such as reconstituted foods and canned tuna. (CalCode, Section114002c).

- Separate food into smaller or thinner portions.

- Hot foods should be placed in shallow containers no more than four (4) inches deep to allow for air circulation around the container.

- Increase rapid cooling of hot foods by the following methods:

- Immersion in an ice bath

- Stir food frequently using ice paddles

- Cover food loosely or leave uncovered to facilitate heat transfer

- Reheating of Foods

Reheated internal temperature must be 165˚F for 15 seconds for potentially hazardous food that has been previously prepared, cooked, and cooled. - Hot Home-Delivered Meals (as applicable for participating sites)

Hot home-delivered meals assembled for next-day and same-day delivery shall be:- Packaged within two (2) hours from the completion of preparation; and/or

- Immediately refrigerated or frozen after packaging, if appropriate.

- Frozen Meals (as applicable for participating sites)

Frozen meals produced in a nutrition services provider kitchen shall:- Be packaged and frozen within two (2) hours at the end of food production, according to the requirements of the CalCode.

- Have temperatures taken and recorded at the end of food production, at the time of packaging and throughout the freezing process. Temperatures shall be recorded and kept on file by the caterer and the nutrition services provider for audit.

- Be packed in individual trays, tightly sealed, and labeled with the date, contents, and instructions for storage and reheating.

- Be frozen in a manner which allows air circulation around each individual tray.

- Be frozen throughout storage, transport, and delivery to the home-delivered meal participant.

- Be discarded according to guidelines from the USDA (United States Department of Agriculture) and FDA (Food and Drug Administration).

HACCP Principals

Hazard Analysis and Critical Control Point (HACCP) is a monitoring system to control and minimize food safety standards. Senior Nutrition Program (SNP) sites are responsible for ensuring food is safe to serve to older adults participating in the meal program. Following HACCP guidelines allows for thorough monitoring to ensure food is safe for consumption. The HACCP plan comprises of seven principles.

-

Analyze Hazard

Identify the sources and severity of potential biological (e.g., a microbe), chemical (e.g., a toxin), or physical (e.g. glass or metal fragments) hazards that may arise during food preparation process and determine preventive measures. It also involves identifying the food production steps that the food goes through from the beginning to end.

Items to analyze during meal preparation include:- Food that is served without cooking such as salads, fruit, and cold cuts.

- Food that is cooked for immediate consumption, such as grilled meat.

- Food items that are prepped, cooked, held, cooled, reheated, and served, such as chilies, soups, and sauces.

- Foods that are simply prepped and stored, such as potato salad and coleslaw.

-

Identify Critical Control Points (CCPs)

These are the points in a food’s production-from its raw state through food preparation and service to consumers-at which the potential hazard can be controlled or eliminated.

Examples of CCP include:- Receiving foods from supplier

- Storing the food before preparation

- Food Preparation/Food Handling

- Cooking

- Hot holding

- Cold holding

- Reheating

- Transporting prepared food to a different location

-

Establish preventative measures with critical limits for each control point

Establishing critical limits at every CCP provides easy-to-follow guidelines in keeping food safe for consumption. For example, in order to kill bacteria, raw chicken breast needs to be cooked to an internal temperature of 165°F for 15 seconds. This minimum of 165°F for 15 seconds is the critical limit, and this critical limit can be met by cooking the chicken breast on the grill for the appropriate amount of time. - Establish procedures to monitor the critical control points

The monitoring step ensures that the critical limits are being met. For example, if a critical limit for cooking chicken is 165°F, then the monitoring system would be to use a thermometer to check the temperature and recording it on a temperature log. -

Establish corrective actions

Corrective actions are necessary when the critical limits are not met. For example, if cooked chicken does not meet minimum cooking temperatures, then it should be cooked longer until it has reached the critical limit of 165°F for 15 seconds. If a food is contaminated, the corrective plan should include disposal of the items to ensure the food is not served to the clients. - Establish procedures to verify that the system is working properly

To ensure food is safe to prepare and serve, SNP sites should check and verify the devices (e.g., thermometer) and/or equipment (e.g., refrigerator or freezer) work properly. This requires periodic calibration of thermometers and daily documentation of refrigerator and freezer units. Additionally, verification procedures include observation of employees’ actions, such as taking temperatures and filling out a temperature log. -

Establish record-keeping and documentation procedures

Keeping accurate records allow SNP sites to effectively respond to food safety hazards. Documentation to keep include Temperature Logs, notes about when corrective action was taken, and information about the maintenance and service performed on equipment. SNP sites are required to maintain records of temperature logs. These records should be accessible for review and inspections.

Meal Service Requirements

- Temperature Maintenance or Holding Time

To maintain quality in prepared foods, holding times shall be kept to a minimum. Long periods of holding hot foods at required temperature diminish the nutrient content and the palatability of foods.

.png)

- Foods can be kept safe by minimizing the time they spend in the temperature danger zone (41°F–135°F). When food is in the Temperature Danger Zone, pathogens grow and multiply at a fast rate and can make food unsafe to eat.

- Temperatures of food during the holding time shall be maintained at 135˚F or above for hot foods and 41˚F and below for cold foods. (CalCode, Section 113996)

- Pasteurized milk and pasteurized milk products in original, sealed containers, and raw shell eggs may be held at or below 45˚F. (CalCode, Section 113996(c3).

- Holding time between the end of production and the beginning of food service at the congregate site or the delivery of the last hot home-delivered meal shall not exceed two (2) hours.

-

Systematic Temperature Checks

Taking and recording food temperatures with an accurate stem thermometer is critical to ensure the safety of food is served to older adults participating in the meal program. Systematic temperature checks of food shall be taken, documented, and filed on-site.- Congregate food temperatures shall be taken daily at the end of food production, upon meal delivery, and/or at the time of service.

- Temperatures of hot and cold foods shall be documented either on the production menu or temperature logs.

- Temperature records shall be sent via e-mail or fax to your assigned SNP RD at the end of the month.

- Temperature records shall be kept on-site for one fiscal year for monitoring and auditing purposes.

-

Handling and Use of Leftovers

- Leftover foods prepared On-Site shall be handled and used in the following manner:

- All leftover foods shall be covered, labeled, and dated.

- If cooling of food is required prior to storage, site should follow the Cooling Procedures of potentially hazardous food. (CalCode, Section114002)

- Refrigerated leftover food shall be used within 3 - 4 days. Frozen leftovers held at 0˚F shall be used within 30 days. (County)

- Priority shall be given to serving leftover foods as seconds to congregate participants unless the food items can be used again in a recipe at the cook-on site. (County)

- Serving leftover food as seconds to congregate participants shall be “first come, first served” after the call for seconds has been announced. (County)

- Leftover foods cannot be counted as additional participant meals or eligible for meal reimbursements.

- Leftovers are not to be taken home by staff or volunteers.

- Leftover foods prepared for Catered Sites shall be handled and served in the following manner:

- To minimize leftovers, order only the number of meals needed and/or use consistent portion control.

- Leftover foods may be served as “seconds” to participants. However, leftover food cannot be counted as additional meals or eligible for meal reimbursements.

- Food in original unopened containers and has been maintained at proper temperatures such as packaged salads, vegetables, fruits, milk, or bread may be saved and serve by best-by date.

- All other foods shall be discarded.

- Leftovers are not to be taken home by staff or volunteers.

- Leftover foods prepared On-Site shall be handled and used in the following manner:

- Foods Taken from Sites

- Foods shall not be taken from the sites by kitchen staff, volunteers, participants, or other individuals.

- If food is removed from the congregate site by the participant, food safety is the responsibility of the recipient.

- Congregate sites shall not provide take-home containers, foil, plastic wrap, bags, etc. for the removal of leftovers by participants.

- Congregate sites shall post signs stating: “Do Not Take Senior Nutrition Meals Home. Meals are only to be consumed on-site.” (Form: Do Not Take Meals Home)

- Site Manager and/or SNP staff shall educate participants regarding sources and prevention of foodborne illness.

- Reservation System

- To help reduce the number of leftover foods, it is recommended that nutrition sites use a meal reservation system.

- Use of such a system shall not exclude eligible participants who have not made reservations.

- "Offer vs. Serve"

- Participants may be permitted to decline any food component required or offered at lunch. "Offer vs. Serve" may also apply to portion size

- Food Transport

- All food for congregate meals shall be packaged and transported in a manner which protects it from potential contamination, including dust, insects, rodents, unclean equipment and utensils, and unnecessary handling.

- Assembling and transport equipment shall be capable of supporting or maintaining appropriate food temperatures.

Temperatures for Food Safety

- It is required that food temperatures be taken just before meals are served.

- Use an NSF (National Sanitation Foundation) food thermometer to check temperature of food.

- Before and after testing all food items, wash thermometer probe with soap and hot water, rinse and shake dry. Sanitize probe with alcohol swabs.

- Hot Foods

- Insert sanitized thermometer about halfway into contents or past the indentation on the needle at the center of the pan. Thermometer should not touch the bottom of the pan.

- If a Thermocouple or digital thermometer is used, record the temperature on the digital display.

- If an “Instant Read" Bimetallic-coil Thermometer is used, record reading when needle of thermometer dial has stopped moving.

- Cold Foods

- To check temperatures of milk, use the following guideline:

- Open a milk carton.

- Insert the sanitized thermometer into the carton.

- Take a reading and record temperature onto the Temperature Log.

- This test milk carton may be used for cooking or for coffee but is not to be served to a participant.

- Tossed green salads and other prepared salads require time-temperature control.

- Whole fresh fruits and breads do not need to have temperatures taken. However, proper storage procedures must always be observed.

- Take temperatures on all other cold perishable foods especially those containing mayonnaise, eggs, meats, and dairy products.

- All cold perishable foods must be refrigerated until ready to serve.

- To check temperatures of milk, use the following guideline:

- Record temperatures of hot and cold food on the production menu or temperature log (Form: Food Temperature Recording).

- Send temperature records via e-mail monthly to assigned dietitian.

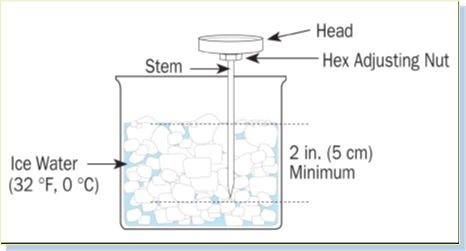

Thermometer Calibration

Only NSF rated food thermometers must be used. Digital Thermometers must have batteries replaced often. Digital thermometers cannot be calibrated. Manual thermometers must be calibrated weekly, and any time the thermometer has been subjected to extreme temperatures or it has been dropped. This is done via Ice Water Method or Boiling Water Method.

- Ice Water Method

- Fill a 2-quart measure with ice.

- Add water to within 1 inch of top of container.

- Stir mixture well.

- Let sit for one minute.

- Place thermometer in container so that the sensing area of stem or probe is completely submerged over the dimple.

- Keep the thermometer from touching sides or bottom of the container.

- Let thermometer stay in ice water for 30 seconds or until the dial stops moving.

- Place the calibration tool on the hex adjusting nut and rotate until the dial reads 32°F, while in ice water.

- Repeat this process with each thermometer.

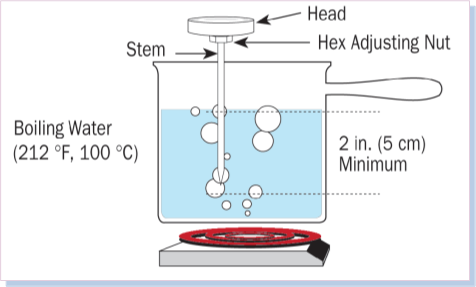

- Boiling Water Method

- Fill a saucepan or stockpot with water.

- Bring water to a rolling boil.

- Place thermometer in the container so that the sensing area of the stem or probe is completely submerged over the dimple.

- Do NOT let the thermometer stem/probe touch sides or bottom of the container.

- Let the thermometer stay in the boiling water for 30 seconds or until the dial stops moving.

- Place the calibration tool on the hex adjusting nut and rotate until the thermometer dial reads 212 °F, while in boiling water.

- Repeat process with each thermometer.

Note: Thermometers should be stored separately in a clean covered container to prevent cross-contamination of the stem probe.

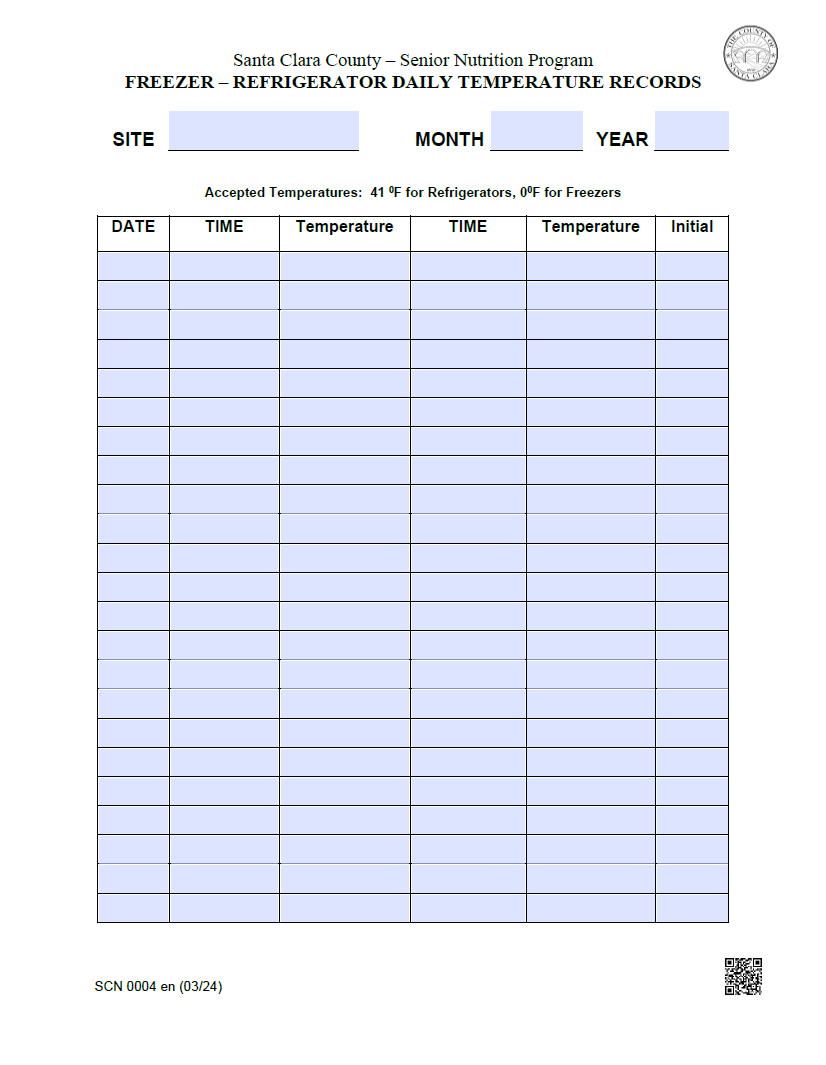

Recording Refrigerator and Freezer Temperatures

- Each cooling unit must have an interior thermometer even if an exterior thermometer is built-in.

- Each senior nutrition site is to maintain a daily temperature record of refrigerators, milk coolers, and freezers. Document temperatures on Form: Freezer/Refrigerator Records.

- Temperature checks should be done in the morning before any of the cooling units has been opened to ensure the most accurate reading.

- Read the thermometers located inside the cooling units.

- Refrigerator temperature should read 41°F or below.

- Freezer temperature should read 0°F or below.

- If temperatures are not within normal limits (above 41°F for refrigerators and milk coolers and above 0°F for freezers):

- Service is required to bring temperatures to normal range.

- Perishable food may need to be discarded per CalCode.

- Record any action taken to correct temperatures, i.e., “called for repair,” “work order submitted,” etc.

- Keep records on file for audit purposes.

Note: Freezer temperatures may fluctuate during “defrost mode.” Keep filters clean on all cooling units.

Forms

Form: Cool Down Log

Form: Do Not Take Meals Home

Form: Food Temperature Recording

Form: Freezer/Refrigerator Records